RHEINZINK double standing seam

The reliable double standing seam roof system made from titanium zinc

Benefits of the RHEINZINK titanium zinc double standing seam

- Long-lasting roof system for traditional and modern architecture from 3° roof inclination

- System approved by building inspection authorities for improved reliability

- Extensive range of semi-finished products and matching roof drainage products from a single source

The RHEINZINK double standing seam

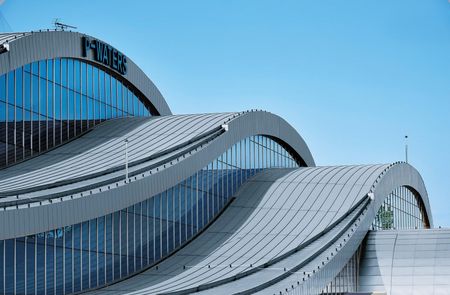

The double standing seam as a system for the roof covering has its origins in the related hollow seam and single standing seam systems. It is a further development of a tried-and-tested system that can be used more favourably in some areas. However, excellent product quality is not the only important aspect for RHEINZINK. Our double standing seam system is also optimised with regard to other areas. Planners and architects benefit from a clearly defined product programme that includes scope for individual solutions as well as the standard products. Refined system technology makes installation of the double standing seam system effortless and cost-effective, which will satisfy the clients of planners and architects. It is particularly simple to install on new buildings. In contrast, it is the flexibility of double standing seam systems that make them ideal for refurbishing existing buildings. Suitable solutions that reduce the complexity of planning and simplify calculation are available for unusually shaped buildings and building elements.

RHEINZINK double standing seam programme

Features of RHEINZINK double standing seams

Double standing seam coverings have many impressive benefits.

- The particularly delicate seams have an attractive, slim appearance and ensure the harmonious integration of roof surfaces in traditional or modern buildings

- Double standing seams are ideal for shallow roof slopes and can be used starting from a gradient of 3°.

- They can be perfectly adapted to various building elements for existing buildings with more complex architecture. Tapered, concave or convex rounded surfaces can be accurately formed

- Standing seam panels up to 7 m long are economical to fit. Panel lengths of up to 16 m can be flexibly employed, including on roofs with large surface areas. We can provide rental machines for processing greater lengths on site.

- The seams are rainproof and so protect the building structure against wind and weather

Planners and professional specialists can also decide whether to produce the double standing seams manually or using a profiling machine.

Double standing seams planning and application

System description

- Roofing from 3° (approx. 5.2%) roof inclination

- Use of seam sealant tape on roofs with inclinations from 3° to 7°

The double standing seam can be fitted on roofs with inclinations from 3°. Seam sealant tapes must be used on roof inclinations from 3° to 7° and where there is a danger of ice dams forming near the eaves. The profile edges are produced using roll formers or by hand. The seams are also sealed using a seam sealer machine or by hand.

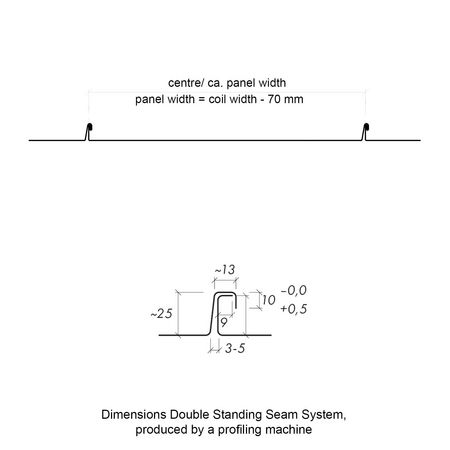

The installation of pre-profiled double standing seam panels has become established as an international standard. Roof surfaces can be very finely segmented thanks to the seam height of approx. 25 mm and slender seams.

Concave and convex rounded surfaces can also be easily roofed using double standing seam systems.

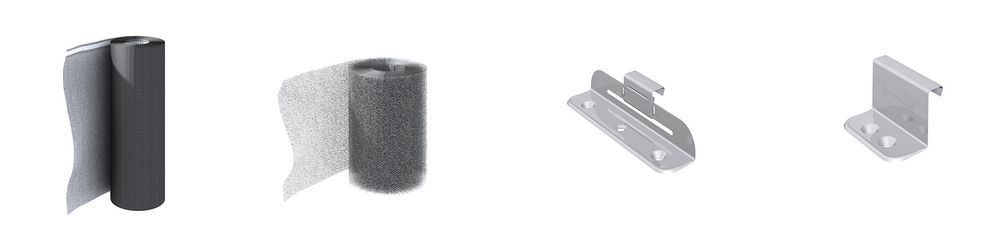

Double standing seam systems are of impressive product quality and are based on well-engineered system technology. For instance, perfectly matching sealant tapes are available for roofs with low gradients and are especially necessary in regions where snow and ice are common.

Double standing seam systems are attached using fixed and sliding clips made from high-quality stainless steel. The screws are corrosion-protected and also fulfil the high requirements for a long-lasting roof covering. The RHEINZINK CLIPFIX autofeed screwdriver and specially developed RHEINZINK clips are available for rapid and stormproof assembly. All relevant technical details can be downloaded from our web page.

Dimensions and metal thickness

The international standard size for roofs in double standing seam systems is a panel width of approx. 530 mm (coil width 600 mm) and a metal thickness of 0.7 mm. We recommend limiting the panel width to 430 mm and the metal thickness to 0.8 mm for mono pitch roofs with overhangs based on practical construction experience. This measure prevents noises that can occur in strong winds due to the natural curvature of the panels.

The generally common maximum panel length is 10 m. Using our clips, this can be extended to 16 m. However, the roof inclination then remains limited to max. 30°. In this case, panel attachments and connection details must be adapted to the increased length variation.

If the max. possible panel length is insufficient, individual lengths can be connected using cross seams.

Customised forms

- Convex and concave rounded panels

- Tapered panels

The minimum radius for convex rounded, standing seam panels is 0.6 m. Starting from a radius of 12 m, panels can be installed without first pre-rounding them. If the radii are smaller, the panels must be edged by hand and stretched using manual forming pliers or a Biegeboy bending machine.

For concave rounded surfaces, the seam edge must be compressed, which is more technically difficult than stretching. The minimum radius for concave rounded, standing seam panels is, therefore, 2.5 m. Pre-rounded panels cannot be installed above a radius of 25 m.

Tapered panels are used to construct roofs over round floor plans or for special details in roof valleys. For reasons of production feasibility, the panel width of tapered panels must be at least 100 mm and max. 730 mm, depending on wind loads. The max. panel width of 530 mm must be adhered to for mono pitch roofs.

Questions on double standing seams

The RHEINZINK team is available to answer questions concerning our double standing seam system and all our other system solutions at any time by phone or via email. If you are not yet familiar with double standing seams, you can find out about them by visiting one of our many specialist dealers or professional specialists. Find retail and specialist partners near you using our dealer and specialist locator.

Downloads

- Standard DetailsAbutment, Linitherm, rendered wall connectionDouble Lock Standing Seam - Linitherm

- Delivery ProgrammeAIR-Z and VAPOZINCProduct Information - structured mat and the structured underlay

- Standard DetailsBox gutter to a parapet wall, safety waterproof layer, structured underlayDouble Lock Standing Seam - vented

- Declarations of PerformanceDeclaration of Performance Dowel-type fasteners CLIPFIX stainless steel with EN 14592

- Declarations of PerformanceDeclaration of Performance Dowel-type fasteners CLIPFIX steel with EN 14592

- Declarations of PerformanceDeclaration of Performance Standing seam panel with EN 14783

- Declarations of PerformanceDeclaration of Performance Structured underlay VAPOZINC with EN 13252

- Planning DocumentsDesign Recommendations for Roof Coverings