AESTHETICS WITH RESPONSIBILITY. RHEINZINK & CO2 reduction

Real sustainability with an excellent eco balance.

RHEINZINK has a proven track record of excellent environmental performance. With our sustainability strategy, we are constantly working to further increase the share of renewable energies, reduce consumption and thus also contribute to the reduction of CO2.

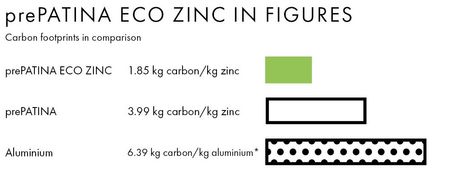

With prePATINA ECO ZINC, RHEINZINK now offers the most sustainable construction zinc in the world. We procure the material from Scandinavia, where it is produced with 50% less CO2. From real renewable energies, certified and without compensation.

prePATINA ECO ZINC

RHEINZINK makes the difference.

The primary energy content of a product indicates how much energy is needed to produce it. From the production of the raw materials to the actual production and transport. RHEINZINK has had an environmental product declaration drawn up according to internationally recognised standards. The result proves: RHEINZINK requires very little manufacturing energy. With only 4.9 kWh for the production of 1kg of titanium zinc from RHEINZINK in the highest finishing stage, RHEINZINK requires significantly less energy than manufacturers of comparable construction metals. Our contribution to CO2 reduction.

Not a supply-critical raw material.

Zinc ore, the raw material from which everything starts, can be mined in many parts of the world. It is not a supply-critical raw material, as the European Commission explicitly emphasises.

Another path to CO2 reduction: short distances.

We obtain more than 90% of our raw zinc from Europe, especially from Scandinavia This is also where the use of renewable energies is by far the most advanced. Our two production sites are also located in the middle of Europe – in Germany and France. The short transport routes are an important component in reducing CO2.

200°C less for a better energy balance.

RHEINZINK is melted, cast, rolled and wound into strips of different thicknesses in a single operation. In the process, we make use of its natural, low melting point. Because less heat input also means less energy input.

The most sustainable construction zinc in the world.

prePATINA becomes prePATINA ECO ZINC with 50% less CO2

50% less CO2 emissions – with prePATINA ECO ZINC, we are taking a big step forward in the reduction of CO2 in the construction industry. Compared to other construction metals, RHEINZINK has long required very little manufacturing energy. With prePATINA ECO ZINC, we are taking the next step in our sustainability strategy towards decarbonised production. As a measure to reduce CO2, it is the first product in which we use only raw materials that were produced with genuine renewable energies.